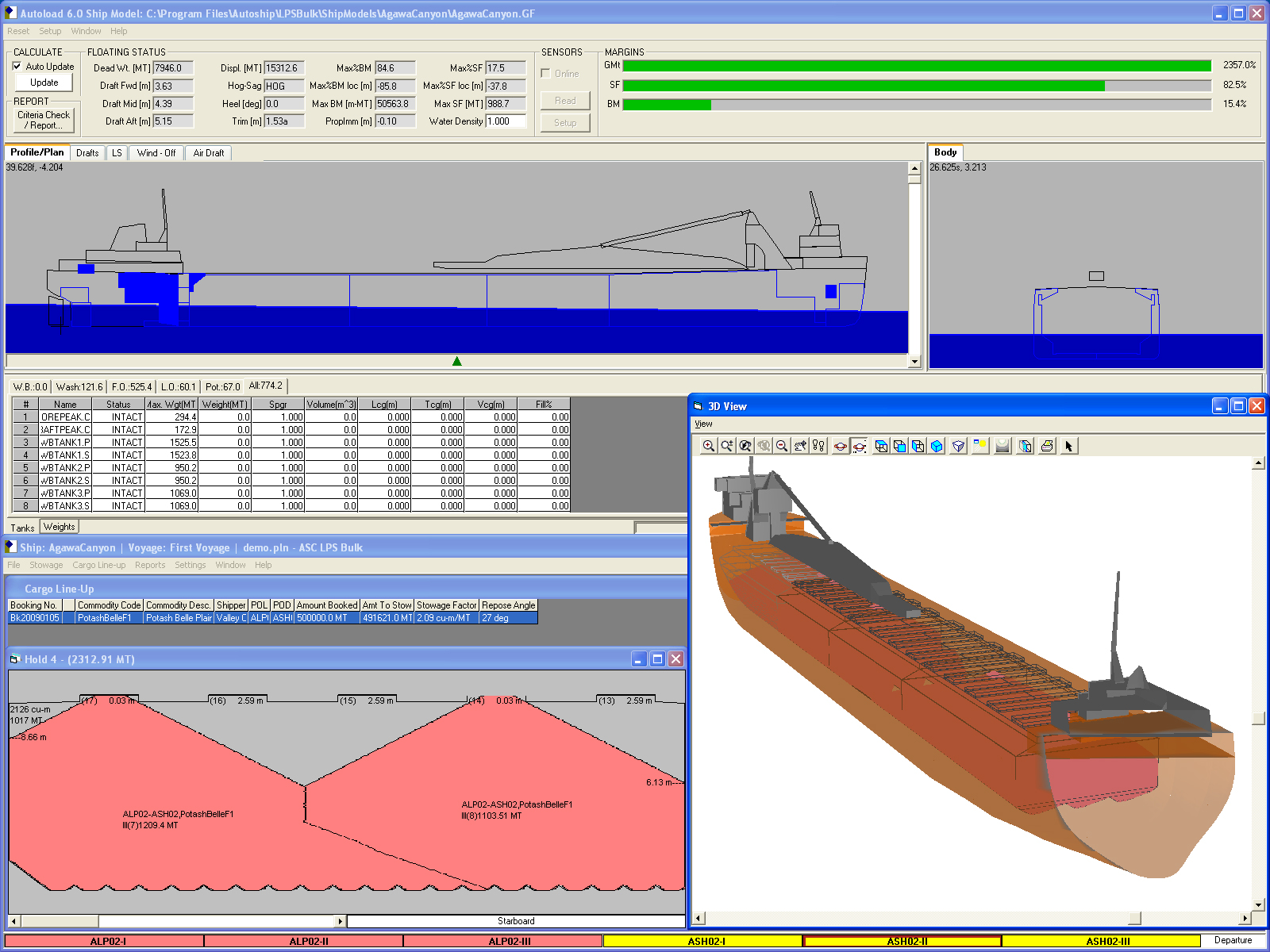

An Integrated Stowage Planning System (SPS) for Break Bulk, Container, and Bulk Cargo Vessels

Westwood Shipping Lines

Stowage Planning System (SPS) for Westwood Shipping Lines (WSL) includes two graphical cargo management modes: break-bulk and container cargo vessels, and a comprehensive hydrostatics analysis engine. SPS is integrated with the WSL Business Information System, providing updated booking information to SPS. The SPS program is being used to manage cargo stowage plan development in North America and Asia, as well as to monitor stability and strength aboard all new WSL ships.

Graphical tools and features are used to stow cargo from the booking list on a particular vessel for its entire voyage. SPS takes care of constantly updated booking lists, cargo shifting, space conflict avoidance, and a series of automatic cargo checks. Westwood’s main breakbulk cargo – lumber and wood products – may be stowed by stowage factor, units of cargo, or by board feet measure. Container cargo is stowed according to characteristics and loading/unloading priorities. Out of gauge cargo and unitized cargo are easily accommodated, while cargo which falls under the category of dangerous goods is clearly indicated in the interface. SPS performs IMDG Code segregation checks during stowage planning.

SPS uses accurate 3D digital models of each vessel for the cargo management modules as well as the hydrostatic engine. Therefore, the stowage plans provide accurate spatial and weight distribution data, and the hydrostatic engine provides accurate calculations – instead of simply being interpolated from a set of pre-existing data.