CAD/CAM Roots

In 1980 Autoship Systems began building a reputation for excellence in software development with a rather revolutionary idea – an integrated suite of PC-based marine CAD/CAM software and services. This innovation established us as market leaders around the world, being the first with Windows-based software, an industry pioneer in NURBS mathematical modeling, and first with an international dealer network. Today, Autoship retains its traditional CAD/CAM market presence through product innovation, excellent after-sales service, and thousands of installations.

Innovations for the Shipping Industry

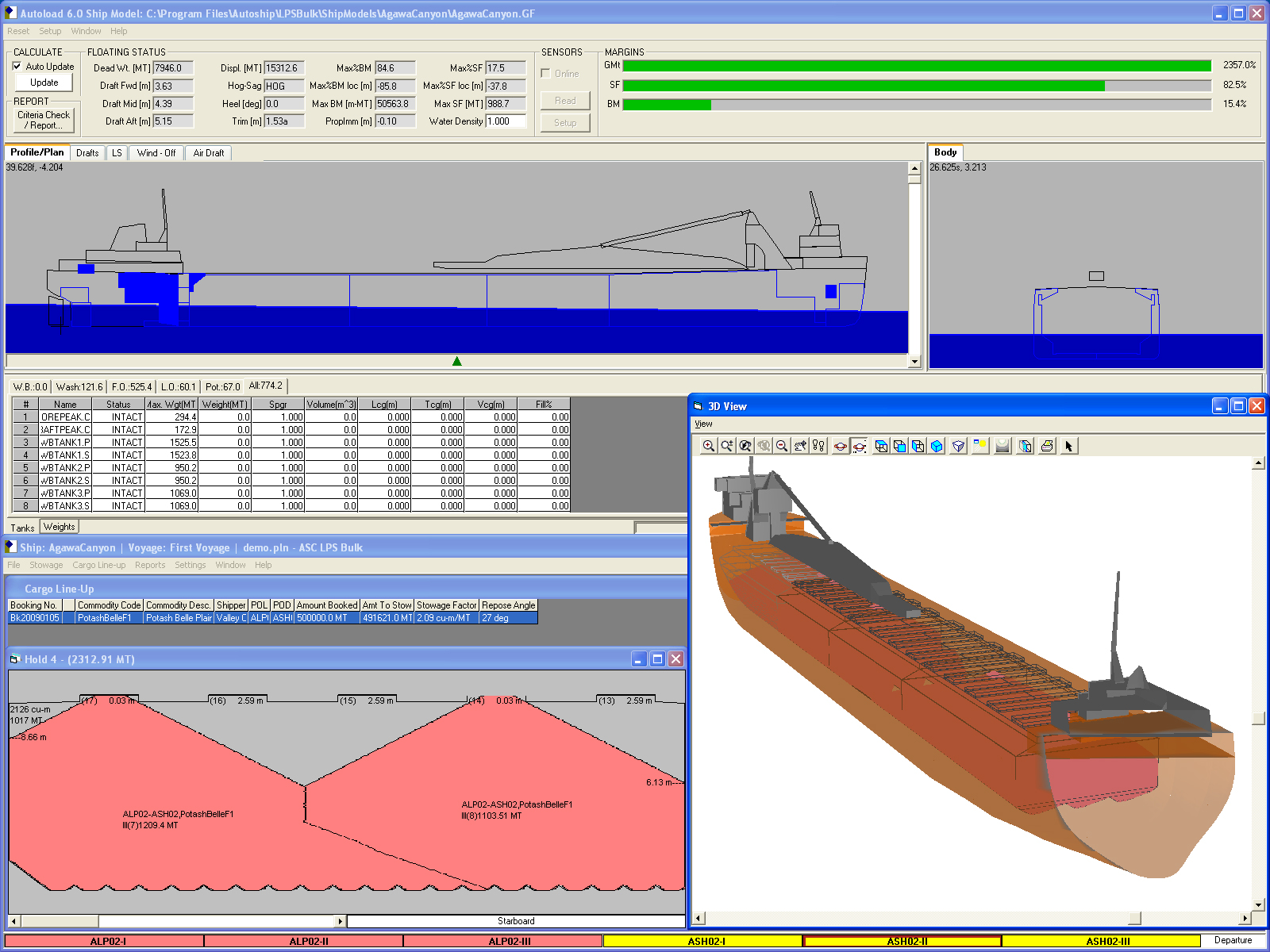

As Autoship began providing more and more specialized marine CAD/CAM software, we perceived a need for a truly accurate hydrostatics engine. Most digital hydrostatic engines were, and still are, based on calculations that interpolate predetermined graphs, while from the start our Autohydro products were based on an accurate digital model of the vessel. It wasn’t long before vessel operators saw the advantages of a truly accurate hydrostatics engine that could be taken to sea on a PC, and so Autoload was born. Autoload has been an extremely successful offshoot – selling to a truly astonishing array of international customers in all operating environments. Autoload continues to sell as a primary hydrostatics calculation engine, able to take into account tanks and distributed weights, and also able to accept data from tank, draft, and rate of flow sensors.

The next step for us, however, became very clear. Cargo had been taken into account by Autoload as distributed weight – but why not keep track of all cargo stowed on a vessel, and have Autoload update its calculations each time a cargo item is stowed?

Two factors were evident: first, cargo placement on shipping vessels remained fluid practically up to the moment of sailing; and second, the marine shipping industry was falling behind in both supply chain management and the e-logistics chain. Cargo was beginning to be tracked electronically from manufacture, through land and air transport, to distribution and dealerships; however, there was (and still is) a glaring gap in supply management when products hit the marine shipping links in the chain. Another gap appeared when it became evident that some smaller companies wanted to be able to automate cargo planning, but could not support the worldwide data systems afforded by our larger customers, such as Wallenius Wilhelmsen Lines. We set out to fill these gaps by providing revolutionary and flexible simulation tools, the ability to track cargo at any point once it is accepted as a booking, and (if desired) the ability to access our products through the Internet.

Our success in these endeavors has been rapid. Our first cargo planning work in 1998 centered on breakbulk vessels, and then we moved to ro-ro and container vessels. We have since gained contracts with tanker and bulk cargo shipping lines, and are expanding into terminal planning and management products. Concurrently, we have developed a type of user-pay access via “thin client” technology; this means that you can now use our stowage planning software via our ISP provider on the Internet, without any system installation or support issues.

Once again, Autoship Systems Corporation is established as the new wave in maritime software; we were never dilettantes, and with over four decades of development history we’re far from being novices.