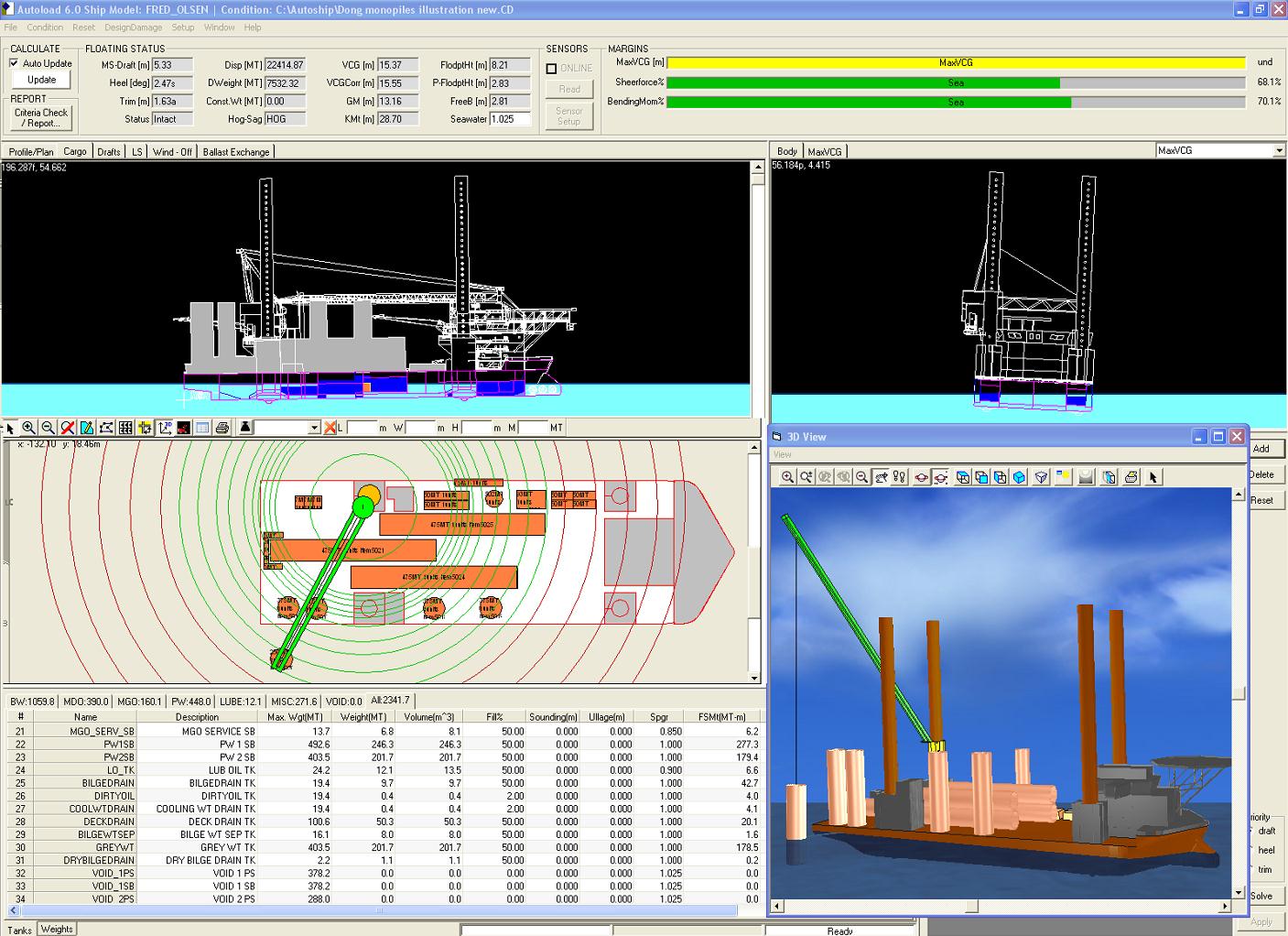

Autoload Jackup

Autoload-Jack up version is developed for the specific need for monitoring and simulation of stability and strength both for free floating (transit) condition as well as jacking up / preloading and elevated conditions.

Key Features:

- Handle intact and damage conditions

- Handle wind in any direction (360 degrees)

- Maxvcg curve and margin bars or direct stability analysis (or combination)

- Compare vessel condition with preset strength and stability limits

- Simulate crane loading and unloading with 3D crane model

- Calculate weight of wire paid out, buoyancy from submerged cargo

- Graphical editing of deck cargo

- Booking list

- Cargo manifest report with graphical layout of deck cargo

- User controlled Library for standardized deck cargo

- Graphical loading of pipe, including water in pipe calculations

- Calculate Dynamic motion parameters

- Perform ballasting sequence

- Perform loading / unloading sequence

- Perform crane ballast sequence, or any other sequence

- Automatic ballast calculations, based on target floating position input by user

- 3D window showing vessel with correct deck load, crane position / load and vessel floating position

- Customizable alert system

- Automatic or manual Draft survey, based on draft sensors or observed drafts at marks. Draft marks and draft sensor positions are configured in the 3D vessel model and ensure accurate calculated results, especially if the vessel is not upright

- User-control of sea water density

- Connects to on-board tank sensors, draft sensors, winch tension sensors and any other sensor readings available in the vessel IAS, such as chain paid out, wind and risers

- Correct tank volumes calculated in vessel 3D tanks with current heel and trim, based on pressure sensor input from IAS

- One license of Autoload for a specific rig can be installed on unlimited number of computers onboard and onshore, with exchange of loading data (for emergency response and redundancy) with no extra cost

- Create readily printable reports, can be exported to Microsoft Word

Additional features for Jacking and preloading mode:

- Individual leg penetration curves saved for each field

- Monitoring of online load / penetration during the preloading phase

- Load / save / report / print penetration curves

Additional features for Elevated mode:

- Calculated Spud can load

- Measured Spud can load

- Max allowable load (set for each field)

- Alarm for max allowable Spud can load

- Calculate Overturning moment and check against Max allowable tipping moment

- Allows independent sea depth for each leg

- Calculate constant (unknown) weight based on measured leg loads

Autoload 3D-viewer – Graphical 3D presentation of crane operation and deck load. Weight crane and hooked load, wire and buoyancy are accounted for during crane lifts. Monitoring of vessel COG and tipping moment, alarm triggered if exceeded. Crane online or simulation (planning).

Free Floating Mode – Leg heights can be set either graphically or numerically. Since Autoload immediately updates the floating position and constantly monitors critical values such as stability and maxvcg a change in leg height will trigger a round of calculations based on the new leg height and the effect on buoyancy, center of gravity and wind area.

Jacking and Elevated Mode – the vessel is considered as semi-floating and in Elevated mode while jacking the vessel is considered not free-floating. In either of these modes a ‘Jack up window’ is used to monitor and simulate all the relevant aspects of operating the vessel in this way. Additionally, various alarms, such as longitudinal strength and over-pressure of the foot pads may be configured.

3rd Party Integration – Autoload can either be fully integrated into the vessel control system or receive sensor data via standardized communication protocols, for tank loads, draft, mooring loads, chain paid out, (chain in lockers), risers, wind or any vessel load measured with sensors.

When on-line, all sensor data are automatically updated to reflect real conditions. Or the operator can choose to work off-line to carry out simulations (what if situations).

Input from vessel IAS

- Tank loads

- Drafts (not available when vessel elevated)

- Crane position and load.

- Winch (wire paid out)

- Leg positions

- Leg loads

- Leg Penetration