Container Vessels

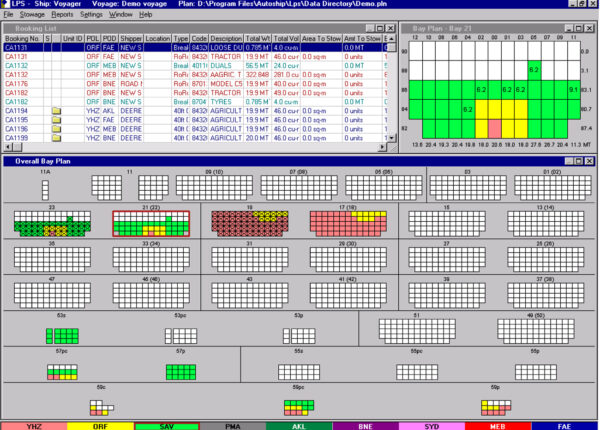

Our container stowage planning module handles both covered deck and weather-deck stowage. Containers can be loaded, re-positioned, and removed at any selected port, with the results of these changes automatically predicted for all future ports in the voyage. Views are easily switched from bay to bay and from port to port throughout the planned voyage:

Stow Cargo by dragging and dropping single or multiple containers from Booking List to the bay selected in the bayplan window, and let the system automatically choose slots within the bay according to user-controlled criteria. Or, you can stow containers in specific slots in a bay, using well-designed dialogues. Other dialogues will appear when stowage management decisions are required, or you can call them when you wish to change stowage parameters. Reposition or remove containers using simple drag-and-drop features. Out of Gauge Cargo is also facilitated.

The software follows default stowage rules and performs automatic and selectable checks during the stowage process. Some of these default stowage rules can be editable.

Usually, the software stores multiple containers using the same method: it first fills the center bottom cell, then the cell immediately to the starboard of the centre cell, then the immediate port cell, and continues to alternate outwards in this starboard-port pattern until the tier is filled. If there is no centre cell, the process starts with the starboard-centre cell. If necessary, the same procedure is repeated for the next tier, and so on. This procedure can be by-passed by loading containers separately. When loading 20 foot containers, this method can be applied simultaneously to two adjacent bays – filling the centre bottom cell in one bay, then the same in the adjacent bay, then continuing to fill starboard and port cells in both bays outward from the centre.

Container cargo modules routinely check for:

|

If any of these checks find a violation of the various required conditions, the system will halt the stowage and notify the user.

All Autoship stowage planning systems include the latest version of our

comprehensive hydrostatics analysis engine – Autoload®